Apricots

Peaches

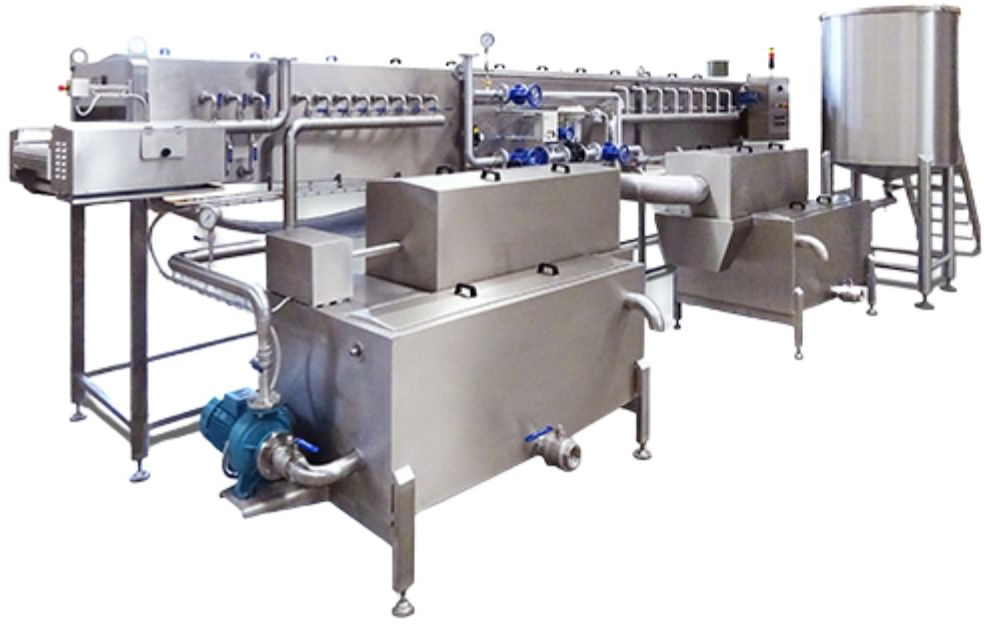

The machine is suitable for chemically peeling pitted and oriented peaches.

It consists of a tunnel divided into three sections where the product undergoes the following treatments:

- Spraying of sodium hydroxide;

- Maceration of the skin;

Cold washing with water that covers the entire surface of the fruit to completely eliminate any residual soda. The conveyor belt is made of a stainless steel mesh with large meshes that allow for thorough washing of the fruit, including the underside.

The peeler is also equipped with the following accessories:

- Heat exchanger for heating the sodium hydroxide;

- Automatic temperature regulation;

- Pump for forced flow of the system;

- Sodium hydroxide preparation tank;

- Sodium hydroxide storage and recovery tank with rotating drum filter;

- Wash water storage and recovery tank with rotating drum filter.

Production and technical specifications vary depending on the customer’s needs, from a minimum of 3 t/h to a maximum of 12 t/h